Tel

0523-8733 8088

Zero leakage butterfly valve

Product overview

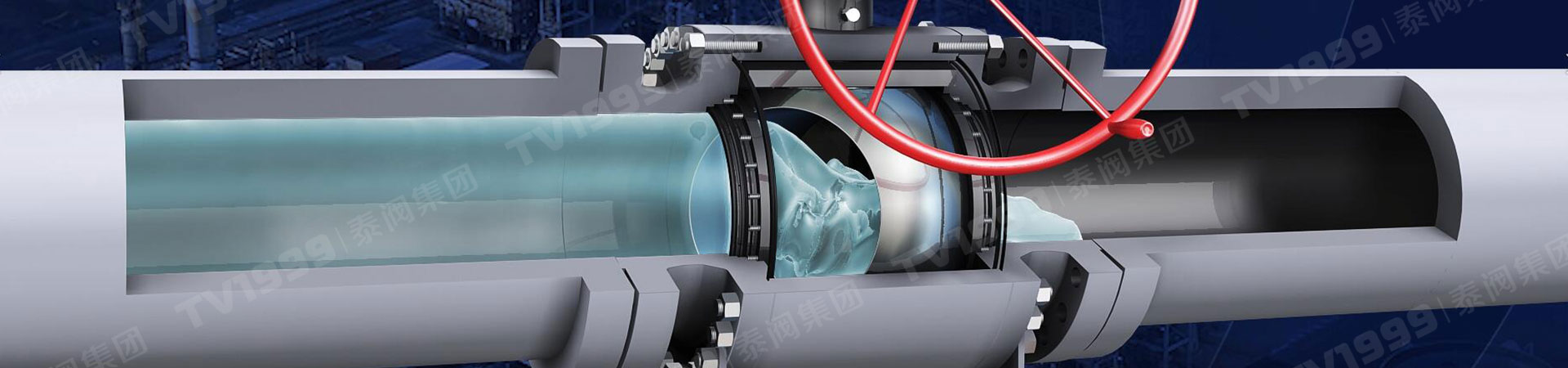

The zero leakage butterfly valve uses non friction metal seals to achieve zero leakage with low torque and has inherent fire safety. The standard valve seat and sealing ring material is stainless steel, while other materials include the available Stellite coating. The elasticity of the sealing ring ensures uniform sealing with the periphery of the valve seat, achieving complete closure regardless of the flow direction. The design adopts the zero leakage principle to idealize the spatial motion trajectory of the sealing surface, with no friction or interference between the sealing surfaces. In addition, the selection of sealing materials is appropriate, which ensures the reliable sealing, corrosion resistance, high temperature resistance, and wear resistance of the butterfly valve. This valve provides a sturdy metal sealing ring for high-temperature and harsh applications to ensure bidirectional closure throughout the entire pressure and temperature range. It can be installed on industrial pipeline networks with a temperature ≤ 425 ℃ for regulating flow and cutting off media.

1. Advanced structure, optimized and innovative design.

2. The seal can be adjusted and replaced, improving efficiency and extending service life.

3. There is no Sliding friction or jamming between valve sealing pairs, with small resistance, low torque and easy operation.

4. Zero leakage structure, opening the seal means separation, and closing the contact means sealing, truly achieving bidirectional sealing.

5. The axial positioning device solves the problem of pressure damage, wear and leakage on the upper and lower sealing surfaces caused by the movement of the axial butterfly plate.

6. Suitable for high temperature and high pressure working conditions, and particularly suitable for working conditions that require high sealing performance.