Tel

0523-8733 8088

Stainless steel elbow

Product overview

Forming process: stainless steel, nickel copper using cold processing, mandrel forming (can greatly reduce the thickness of stainless steel elbow wall thinning problem), carbon steel using hot processing, internal mandrel forming.

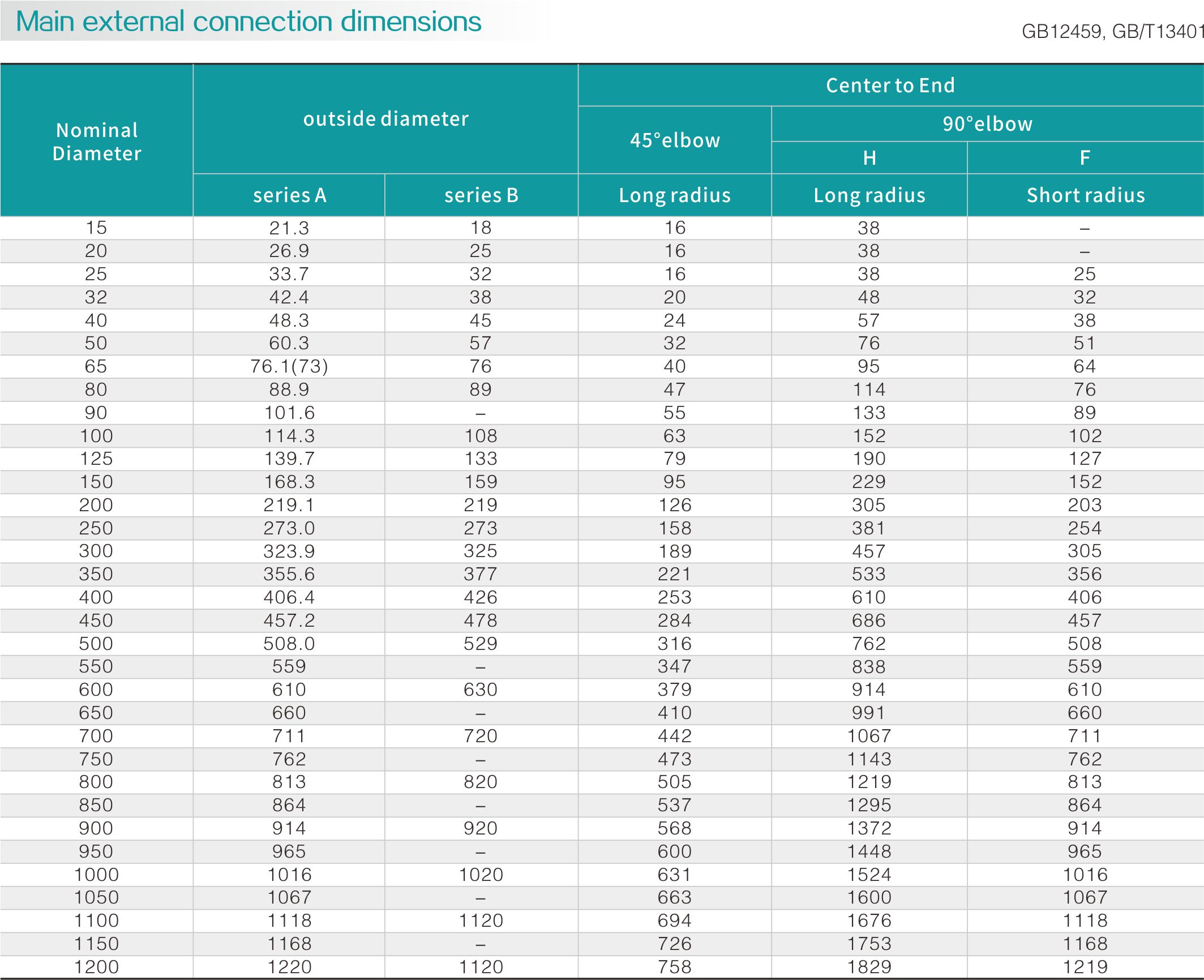

Size: 1/2"-24"(DN15-DN1000)

Standards: GB/T12459, GB/T13401, SH3408, SH3409, HG/T21635, HG/T21631, ASMEB16.9, MSSSP-43, DIN2605, JISB2313

Wall thickness: SCH5S-SCH160

Material: SF2225, SF2205, SF2507, alloy steel, carbon steel, low temperature steel, 304,304 L, 316L, etc

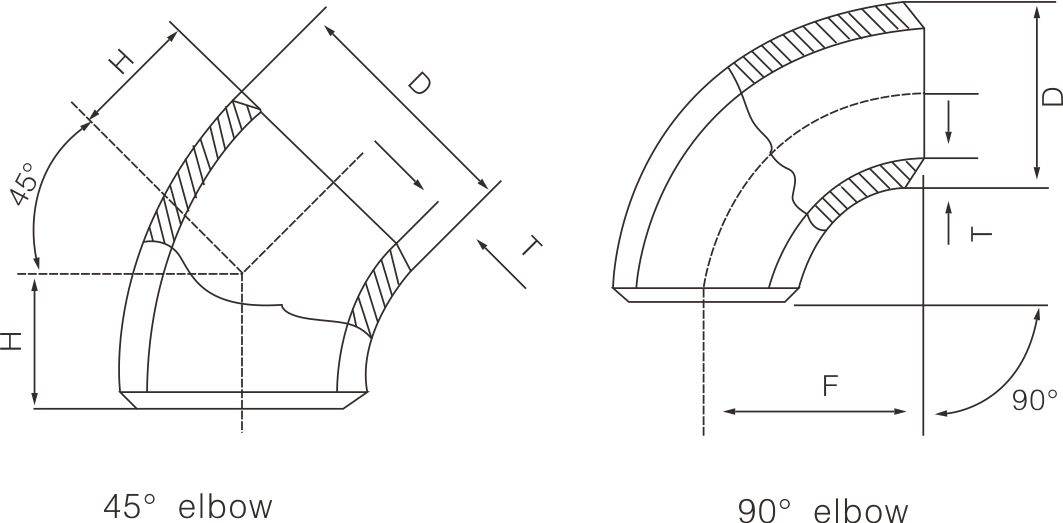

In pipeline systems, elbows are fittings that change the direction of the pipeline. According to angles, there are three commonly used types: 45 ° and 90 ° and 180 °. In addition, according to engineering needs, there are also other abnormal angle elbows such as 60 °. The materials of elbows include cast iron, stainless steel, alloy steel, malleable cast iron, carbon steel, non-ferrous metals, and plastics. The methods of connecting to pipes include direct welding (commonly used) flange connection, hot melt connection, electric melt connection, threaded connection, and socket connection. According to production processes, it can be divided into: welded elbows, stamped elbows, push made elbows, cast elbows, butt welded elbows, etc. Other names: 90 degree elbow, right angle bend, etc